Auto Pigmented Leather Care Kit

Auto Pigmented Leather Care Kit Ap3

People Also Ask:

What is Pigmented Leathers?

Pigmented leathers are opaque pigment coated that is further coated with a clear urethane topcoat which makes them almost non-absorbent.

Where is the weakness in Pigmented Leathers?

The weakness in pigmented leathers is the stitching rows from rain and sun damage are often experienced with water collected slowly seeping through the stitching rows.

Why do Leathers become Dry, Stiff, and Develop Cracks?

Leathers become dry and stiff and develop cracks from these stitching rows that are exposed to the element that leather dryness of its original fat and oil moisture contents evaporates from there. When leather is dry and stiffer, with flexing or stressing, it begins to develop cracks. When the cracking is connected, it will rip or tear under stress.

Why the Need to Recondition the Stitching Rows?

The need to recondition the stitching rows because the cross-section is suede. These weak points of the leather need to be rejuvenated periodically into the leather structure to maintain its reap-tensile strength. Below the tensile tear strength of 1800 psi, the leather is venerable to crack, rip and tear.

Why Recondition with Fatliquor?

Fatliquor is ionic negative -ve charged fat and oil that hydrogen bond with the ionic positive +ve leather protein fiber originally from the tannery.

Fatliquor is a VOC, a volatile organic compound that evaporates through aging or intense heat. Just like our engine oil will need periodic topping up as well. The suppleness of the leather translated to strength depends on the fatliquor. Reconditioning starts when micro crazing develops, including the stitching holes at periodic intervals to ensure long-term suppleness that prevents leather stiffness and cracking.

Why a Cleaning Cycle?

A cleaning cycle keeps appearance at the highest level possible at all times. Reconditioning keeps leather supple, and the protector prolongs the wearing to the finishes.

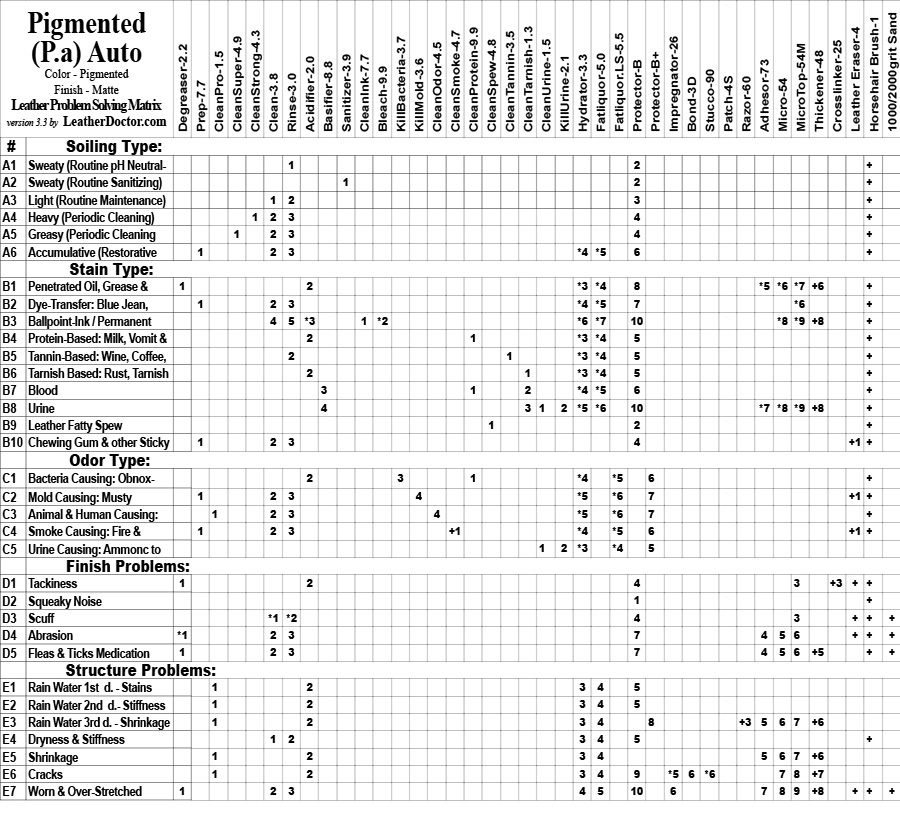

Pigmented (P.a) Auto-Leather Problem Solving Matrix

Pigmented (P.a) Auto-Leather Problem Solving Matrix

Use the leather problem-solving matrix for reference to match specific problems or levels of care.