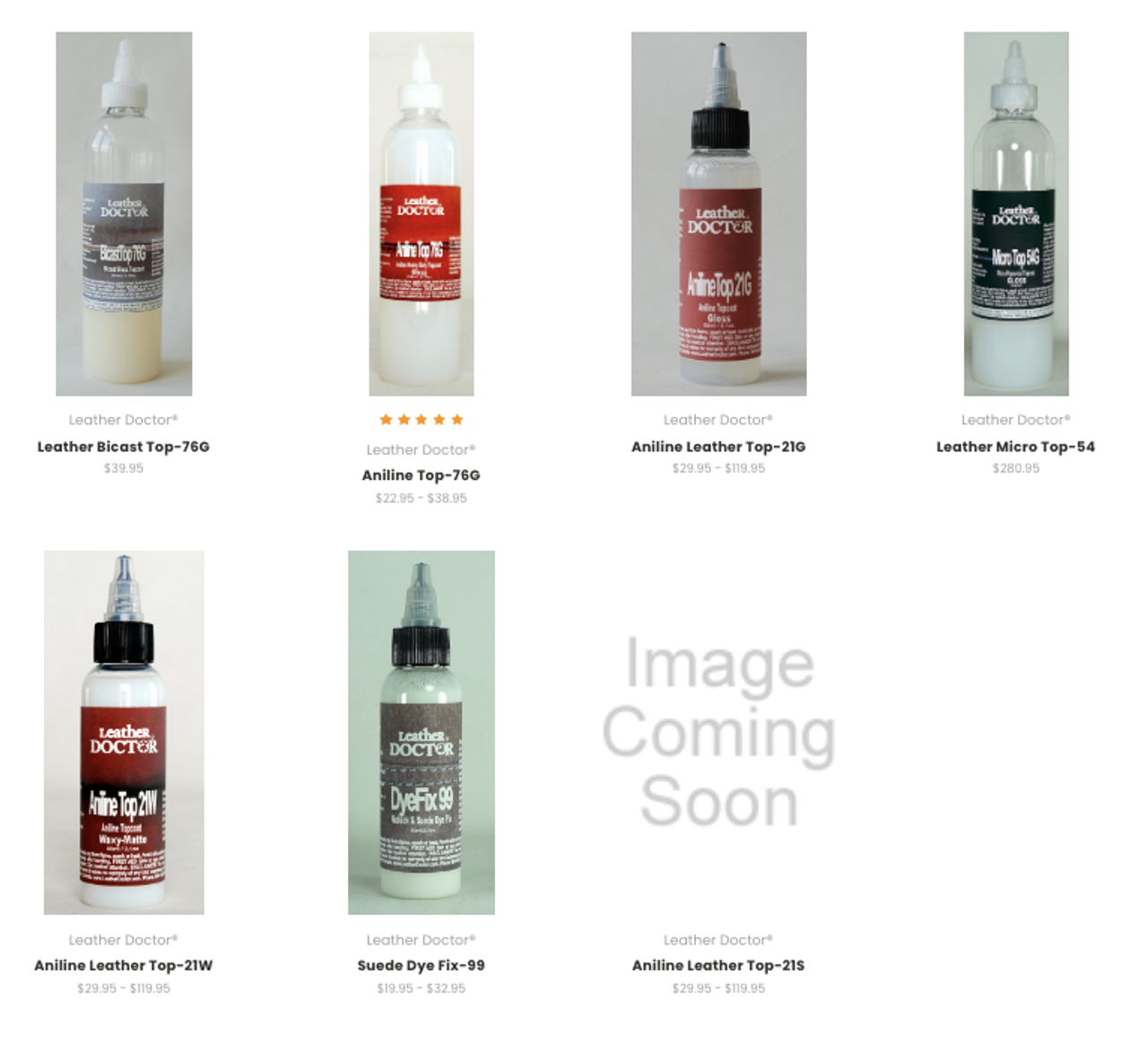

Leather and Suede Topcoat Finishes

Most finished leather will come to a stage that develops topcoat damages as being part of its useful life cycle. Topcoat damages may vary from leather types and it may manifest as stickiness, common to bicast leather from perspiration contamination; scaly flaking or mud cracking to aniline leathers through ageing and streaks from alkaline overexposure are a common occurrence to pigmented leathers. Accidental damages include usage or moving or pet scratches. The objective of the topcoat is to impart a film forming coating that provides abrasion and stain resistance to the colorcoat, besides enhancing the color intensity it also amplifies and magnifies the beauty of the aniline leather crust. Some topcoat forms discontinuous film especially from nitrocellulose that allows greater transpiration to take place. Others will sooner develop micro crazing especially the finer aniline topcoat, while the micro-pigmented leather may take a longer time. When topcoat is cross-linked, its performances increase from stickiness for the common bicast leather sticky problem. A wide variety of topcoats is available, with both ingredient and formulation varied to suite the requirement of the leather usage; not only in terms of luster level like gloss, satin or matte; but also in terms of flexibility and breathability, etc. Ingredient used includes elastomeric, acrylic, nitrocellulose, urethane, etc. Without this topcoat, the color basecoat would be: a) poor in aesthetics such as appearance and feel; b) susceptible to sticking together or attracting loose dust and dye especially in hot humid condition; c) poor physical properties such as wet rub, sweat resistant and scuff resistant; d) poor in ageing properties such as soil resistant and wet cleaning resistant.