Aniline Waxy Matte Leather Topcoat Refinishing Kit AX6.tc by Leather Doctor® is to degrease, clean, rinse, hydrate, soften, refinish, and protect waxed leather.

Waxed Leather is dyed completely to the reverse suede side using a transparent aniline dyestuff, such as Aniline 21. The surface is further enhanced with Aniline 76, which evens out the appearance, and is then sealed with Matte 21 to protect and preserve the natural beauty of the leather grain. A non-stick, rub-resistant conditioner is applied routinely to prevent rubbing wear during regular use. Options include Protector W or the leather-scented version, Protector W Plus. This waxed leather finishing system differentiates waxed leather from other types of aniline leather, such as wax pull-up leather, through its specific topcoat formulation and surface conditioning process.

Leather-degreasing body oils, grease, and sweat are crucial for proper topcoat bonding in refinishing. Since leather is an amphoteric protein material, it is highly pH-sensitive, and the ideal pH range for degreasing should be between 3 and 5. High pH (alkaline degreasers) can cause dyestuff bleeding and displacement, leading to blotchy discoloration. Tanning agents can leach out, making the leather tacky and compromising its structure. Solvent-alcohol-based or alkaline degreasers can remove essential fat liquors, causing stiffness and cracks when the leather is stressed. For aged, cracked, or dried leather, it is recommended to first hydrate and replenish the leather's natural fat and oil content before degreasing. This can be done using the Hydrator 3.3 and Fatliquor 5.0 system, ensuring the leather remains supple and prevents over-drying during degreasing.

Topcoat Refinishing preparation depends on the condition of the existing topcoat and the extent of physical damage. In some cases, partial or total removal of the old topcoat is recommended to create a stronger foundation and achieve a uniform finish.

Here are the Handpicked Products system:

Degreasing & Acidifying system

Degreaser 2.2 is a pH 2.2 water-based degreaser with tackiness and dye bleeding control for penetrated oil, grease, and sweat stains from skin, and hair contact. Degreaser 2.2 charges the leather protein fiber ionic positive (+ve) for strengthening the ionic attraction between the ionic negative (-ve) tanning agent, dyestuff, and fat liquor eliminating most potential side effects, unlike other solvent degreasers.

Acidifier 2.0 is a pH2.0 acidifier rinse for controlling, neutralizing, and pH-balancing leather chemistry integrity against tackiness and dye bleeding. This Acidifier 2.0 works in sequence with Degreaser 2.2 to rinse and pH-balance by charging the leather protein fiber ionic positive (+ve), increasing the attraction between the ionic negative (-ve) leather constituents like the tanning agent, dyestuff, and fat liquor, preventing tackiness, bleeding, and stiffness.

Cleaning & Rinsing system

Cleaner 3.8 is a leather-safe pH 3.8 mild cleaner that is particularly effective in emulsifying and suspending general soilings without common side effects. It works over Degreaser 2.2 and Acidifier 2.0 and extends the entire section without leaving a dry edge. Cleaner 3.8 holistic cleaning and rinsing sequence with Rinse 3.0 returns residue free to its pH chemistry integrity without potential side effects such as rings and browning on pH-sensitive aniline leathers.

Rinse 3.0 is a pH 3.0 rinse for removing suspended soil and strengthening the pH chemistry integrity of leather. It removes suspended soiling by towel extraction while neutralizing harmful alkaline residues and charging the leather ionic positive (+ve) to increase the attraction between the ionic negative (-ve) tanning agent, dyestuff, and fat liquor from tackiness, bleeding, and stiffness.

Hydrating & Fatliquoring system

Hydrator 3.3 is a pH 3.3 hydrating conditioner to relax and stretch out the stiffness, creases, and wrinkles before fat liquoring. It facilitates colloidal water movement, reactivating the dormant dyestuff to resurface and reducing surface inter-facial tension for an even appearance. Hydrator 3.3 relaxes and plumps the leather structure, providing strength for easy stretching and shaving of existing topcoats. The leather structure becomes stretchable against the stiffer topcoats, causing the aging topcoat to loosen for easy shaving, as an option.

Fatliquor 5.0 is a pH 5.0 micro-emulsion of fat, oil, and water for rejuvenating, restoring, and softening leather. Fatliquor ionic negatively (-ve) charged micro-emulsion of fat, oil, and water for conditioning leather softness with strength when dry. Fatliquor 5.0, when applied to leather, causes the water-encased ionic-charged fat and oil molecules to break free and become attracted to the protein leather structure. This process results in free water being wicked away, leaving space for the natural transpiration of the leather.

Top Coating system

Aniline Finish Topcoat Waxy Matte 21

Matte 21 is a water-based emulsion topcoat with a matte luster and a waxy feel that matches the original waxed leather. Its fine particle-size urethane resin protects the aniline dyestuff with excellent toughness and flexibility.

Conditioning system

Conditioner W Plus is a nonstick, rub-resistant, non-film-forming leather scent conditioner that imparts a soft waxy feel to shield the detrimental effects of sticky soiling. Its breathable barrier increases resistance to wet and dry rubs, thus reducing stretch, scuff, and abrasion.

Tools

Brush 1 is a detailing horsehair brush for all smooth leather for soft and scratch-free cleaning. Brush 1 is ergonomically designed as an extension of our hand with a sturdy grooved grip to produce effective results easily and efficiently. Its length is 7 inches with a three-row horsehair 1½ inches cleaning head.

Foam 2 is a 2-inch high-density poly foam brush that resists tearing and shredding and carries more material for controlling and spreading solution for a more even distribution.

This paper towel works like cloth and is lint-free, highly absorbent, stretchable, washable, and strong.

Leather Eraser 4 by Leather Doctor is used on all leather, nubuck, and fine suede for dry and wet cleaning with better greasy and gummy soil traction.

Sandpaper 2000 grit is recommended to remove refinishing streaks for in between coatings.

Instruction:

1. Stripping:

- Stripping is optional depending on the condition of the existing topcoat.

- The chemical stripping option is done with Stripper 2.3 and Stripping Brush 9.

- The physical shaving of the deteriorating topcoat is done with Razor 60 in sequence with Hydrator 3.3 and Fatliquor 5.0 system.

2. Degreasing:

Degreasing is performed with Degreaser 2.2.

- Degreaser 2.2 is shaken to gel before use.

- It is transferred onto Foam 2, Brush 2, or Eraser 4 for better control before applying to the stain.

- It is brushed and suspended soiling extracted with a white absorbent towel changing folding sides until it shows clean, ready for acidifing rinse.

3. Acidifying Rinse:

Acidifying rinse with Acidifier 2.0 follows after degreasing as a rinse and pH balancing system.

- Acidifier 2.0 concentrate 1: 25 is to be mixed with 218g distilled water or 1.5 inches from the top of the 8oz bottle before use.

- It is applied directly, brushed, and extracted with a towel until clean.

- It is kept for 3 to 30 minutes to neutralize and stabilize leather pH.

- Treatment is complete with a healthy squeaky feel, ready for general cleaning.

4. General Cleaning:

General cleaning with Cleaner 3.8 follows after Acidifier 2.0.

- Cleaner 3.8 concentrate 1: 64 is mixed with 224g distilled water or 1.5 inches from the top of the 8oz bottle before use.

- It is applied and brushed with Brush 1.

- Suspended soiling is extracted with a dry absorbent towel until it shows clean and proceed to rinse with Rinse 3.0.

5. pH Balancing Rinse:

A general and pH-balancing rinse with Rinse 3.0 follows after Cleaner 3.8.

- Rinse 3.0 concentrate 1: 80 is mixed with 224g distilled water or 1.5 inches from the top of the 8oz bottle before use.

- It is applied, brushed, and suspended soiling is extracted with a dry absorbent towel, check for a healthy squeak and ready with hydrating.

6. Hydrating:

Hydrating with Hydrator 3.3 follows after Rinse 3.0.

- Hydrator 3.3 concentrate 1: 25 is mixed with 218g distilled water or 1.5 inches from the top of the 8oz bottle before use.

- It is applied and brushed with a deep even saturating appearance, massaged, and stretched to dimension, before proceeding with fatliquoring.

7. Fatliquoring:

Fatliquoring to replenish diminishing fat and oil follows after effective hydration with Hydrator 3.3.

- Fatliquor 5.0 concentrate 1: 5 requires 189g of distilled water or mixing up to 1.5 inches below the 8oz bottle top before ready to use.

- It is applied and redistributed following the same success technique as Hydrator 3.3.

- Its application is repeated each cycle water contents evaporates.

- Its application ends when the leather absorbs no more and is left to natural drying.

- Its dried sticky residue is rinsed off with Hydrator 3.3.

- Fatliquored leather is left to dry naturally for extra softness.

- Fatliquored leather is further staked, massaged, or flexed accordingly with a little wet back with Hydrator 3.3 until dry for extra suppleness.

8. Topcoating:

Topcoating begins when the leather is dry and dry prep well before Matte 21.

- Matte 21 concentrate is mixed with distilled water 1: 3 before use.

- Use a lint-free padding, varnishing brush, or airbrushing for professional results.

- Let dry between applications.

- Use 1000/2000grit as optional between coats.

9. Conditioning:

Conditioning with Protector W begins when the topcoat is dry and cured.

- Protector W concentrate 1:15 is mixed with 212g distilled water or 1.5 inches from the top of the 8oz bottle, before use.

- It is applied with a brush or a folded towel, is left to dry, and ready to use.

FAQ’s

What is Leather Wet Processing?

Wet processing is a continuous dovetailing system that includes the working sequence of Degreaser 2.2 followed by Acidifier 2.0, Cleaner 3.8 followed by Rinse 3.0, and ends with Hydrator 3.3 followed by Fatliquor 5.0. The leather is continuously wet throughout the product applications and is extracted with a white absorbent towel until clean. Hydrator 3.3 is used again after Fatliquor 5.0 to remove sticky residue. It is left to dry naturally, and a little stretching when almost dry produces a softer leather with tensile strength.

What is Leather Dry Processing?

The dry process begins with Eraser 4, and Razor 60 is an option to remove surface residues that may have wicked up. The darkening effect is improved with deep stretching using a tablespoon. Matte 21 is best applied with a folded white lint-free towel like Towel 5 as the first coating to promote adhesion. A New folding side is used when the towel picks up soiling residue. Sand 2000 may be an option between coatings, but sanding on the leather crust alone is not recommended. Protector W marks the end of the Dry Process.

How to work with Matte 21?

The leather is inspected especially the penetrated stained area that typically turns dark when soiling particulates resurface. Stretching or deep stretching with a tablespoon, brushing, erasing, or shaving with optional Razor 60 will lighten the appearance. Any sanding required is after the first coating has dried, to smooth out, without damage to the leather grain. Coating with a lint-free folding towel is recommended as the first coating to ensure adhesion promotion and pick up residual soiling. Other application methods may include foam brushing, a soft touch varnishing brush to reduce streaks, and airbrushing to produce professional results. Let dry between the coatings and further fine sanding to smooth out continues in between coatings to satisfaction. Let the topcoat cure overnight for extra strength and inspection before the nonstick protection application.

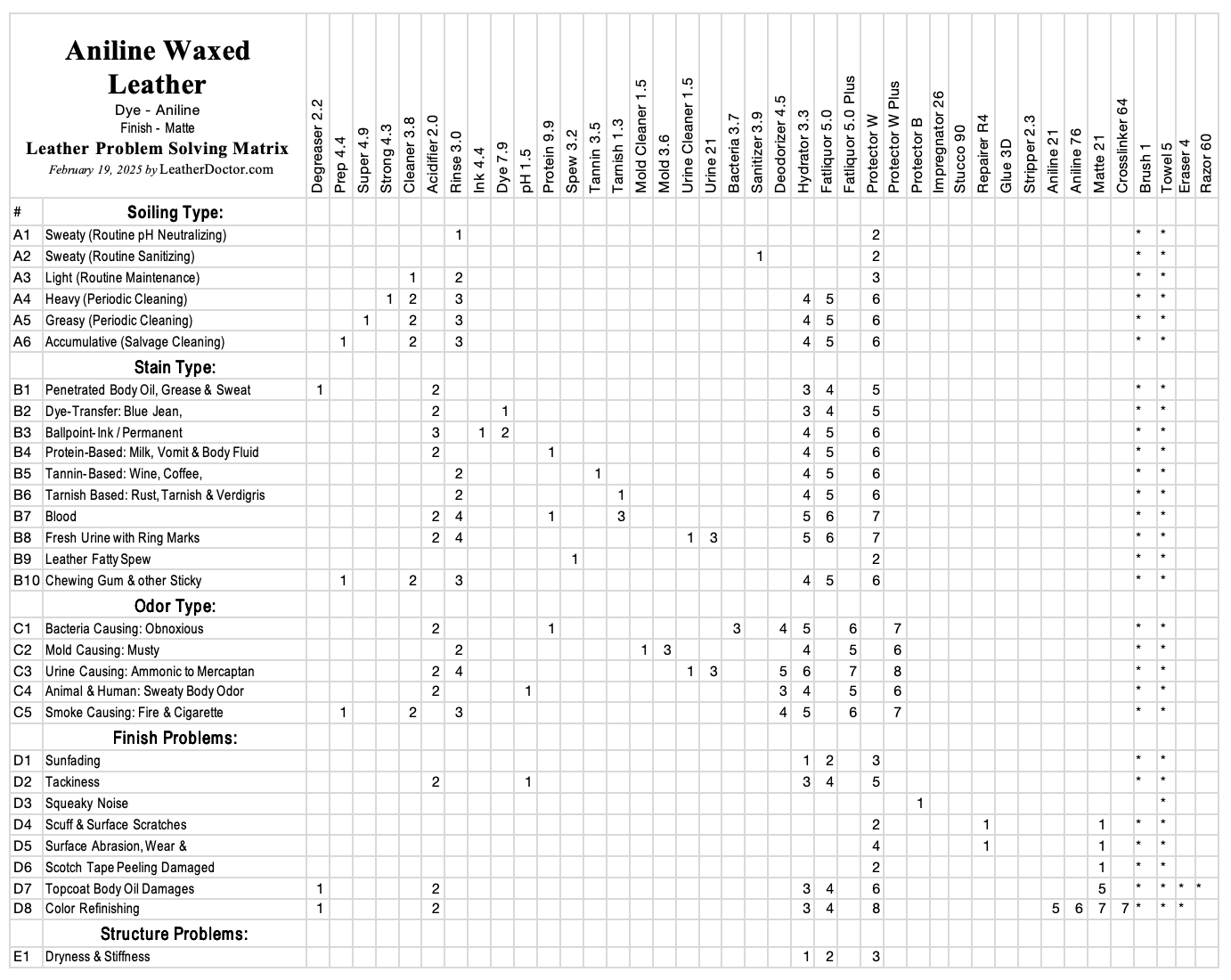

How to Use the Aniline Leather Problem-Solving Matrix?

The matrix categorizes common issues with aniline leather into five groups: Soil, Stain, Odor, Finish, and Structure (listed in the left column). Corresponding recommended products are displayed across the top row. Each number within the matrix indicates the steps required to address the problem holistically.

For example:

If a leather issue involves an unknown compound that combines soil, stain, and odor, follow the sequence across the matrix, combining necessary steps from each category. The process should always conclude with

- Hydrator 3.3 to rehydrate and relax the leather.

- Fatliquor 5.0 to replenish lost fats and oils, restoring suppleness.

- Protector W conditioning the leather for ongoing durability.

Thank you for your input to improve this writing, any comments are welcome.

Edited: March 11, 2025, by Roger Koh