Wax Pull-Up Leather Dye Refinishing Kit AW7.cl by Leather Doctor® is an advanced leather-safe refinishing system formulated to restore aniline wax pull-up leathers to their original showroom condition.

This holistic 8-step system mimics the modern tannery's wet and dry processes, rejuvenating structure, color, pull-up effect, and topcoat finish with meticulous attention to the chemistry and care of delicate aniline leathers.

Designed specifically for aniline wax pull-up leathers that have experienced fading, dryness, or loss of character due to wear or cleaning, this system rebuilds the leather from the inside out—preserving its supple feel, unique pull-up effect, and natural beauty.

8-Step Tannery-Science Refinishing System

1️⃣ Deep Cleaning & pH Balancing

Restore the leather’s pH integrity and prep it for refinishing:

- Degreaser 2.2: Targets and emulsifies embedded body oils, perspiration, and greasy contaminants with a powerful yet leather-safe formula.

- Soft 3.8: A pH-balanced mild cleaner that lifts surface soiling without damaging delicate aniline finishes.

- Rinse 3.0: Neutralizes and rinse suspended residues and reestablishes the optimal pH level (3.0 - 5.0) for safe handling of protein fiber leather.

- Acidifier 2.0: Strengthens the ionic bonding within the collagen matrix and combats alkaline overexposure that leads to dryness and cracking.

- Hydrator 3.3: Rehydrates and relaxes compacted, stiff, or shriveled leather fibers to restore softness and readiness for structural restoration.

2️⃣ Structural Dye Penetration

Restore depth of color with transparent staining dyes:

- Dye 21: A water-based, tannery-grade penetrating dye that enhances the natural grain and character of the leather without masking its beauty. Designed to soak in and form a chemical bond with the leather’s protein structure.

3️⃣ Fatliquoring – Restoring Original Suppleness

Replenish natural oils lost through use and cleaning:

- Fatliquor 5.0: A pH 5.0 anionic emulsion of fat, oil, and water that nourishes the fiber structure from within. Restores suppleness, prevents cracking, and brings back the tactile comfort of luxurious leather.

4️⃣ Pull-Up Effect Restoration

Reintroduce the classic tonal shift of wax pull-up leathers:

- Wax 8.6: Reinstates the signature pull-up lightening effect when stretched or creased, while conditioning the leather with protective waxes that deepen richness and resist aging.

5️⃣ Priming for Adhesion

Seal the grain and create a bonding base for dye coating:

- Primer 73: A compact resin primer that levels the surface, tightens the grain, and ensures optimal adhesion of subsequent color coatings.

6️⃣ Surface Dye Coating

Rebuild the color with vivid brilliance:

- Dye 76: A high-performance water-based transparent coating dye that reinforces color vibrancy while preserving the transparency of the aniline finish. Designed to enhance depth and clarity with a refined gloss.

7️⃣ Topcoating – Protective Finish Layer

Lock in the color and finish with long-lasting protection:

- Gloss 76: A durable, flexible gloss topcoat that seals in the color, restores the original showroom sheen, and protects against abrasion, scuffing, and fading.

8️⃣ Conditioning & Protection

Finish with a tactile enhancement and stain resistance:

- Conditioner B: A pH 3.2 rub-resistant, non-stick conditioner that enhances tactile softness while protecting against frictional wear, dye transfer, and everyday soiling.

Science-Based Restoration for Lasting Results

Kit AW7.cl is ideal for:

- Faded or worn aniline wax pull-up leather jackets, bags, or upholstery

- Restoring pull-up effect and color depth lost through sun exposure or alkaline cleaners

- Conditioning leather to prevent cracking and stiffening

- Clients seeking full restoration back to a vibrant, glossy showroom finish

Kit AW7.cl requires 1731g (1.9 quarts) of distilled waterto be mixed and filled before use, and products are available individually as refills to complete your project.

Kit AW7.cl Product Summary Includes:

✅ Degreaser 2.2 - 4oz

✅ Soft 3.8 - 8oz

✅ Rinse 3.0 - 8oz

✅ Acidifier 2.0 - 8oz

✅ Hydrator 3.3 - 8oz

✅ Dye 21 - 4oz

✅ Fatliquor 5.0 - 8oz

✅ Wax 8.6 - 8oz

✅ Primer 73 - 4oz

✅ Dye 76 - 4oz

✅ Gloss 76 - 4oz

✅ Conditioner B - 8oz

✅ Brush 1

✅ Foam 2

✅ Towel 5

✅ Eraser 4

✅ Sand 2000

Leather Degreaser 2.2 by Leather Doctor® is a professional-grade, water-based solution formulated to remove body oils, grease, and sweat from leather surfaces.

Deep-Cleansing, Leather-Safe Degreaser for Aniline Wax Pull-up Leather.

Degreaser 2.2 Key Benefits:

- Ideal for use on body oil, grease and sweat, this powerful cleaner penetrates deep to lift embedded grime while maintaining the integrity of the leather.

- With a pH value of 2.2, Degreaser 2.2 is leather-safe and prevents common issues like dye bleeding and surface damage. Unlike harsh solvent-based alternatives, it cleans effectively without drying out or weakening the leather structure.

Leather Soft Cleaner 3.8 by Leather Doctor® is a leather-safe, pH 3.8 mild cleaner formulated to effectively emulsify and lift general soiling without causing common side effects.

- Soft 3.8 is among the mildest of cleaners with a lower cleaning power than Strong 4.3 and Super 4.9.

Why Choose Soft 3.8?

- Always test clean with Soft 3.8 and evaluate the result to your satisfaction before progressively increasing the cleaning power to Strong 4.3 or Super 4.9.

- Accumulated soiling may require the next level of preparatory cleaners with Prep 4.4.

- Penetrated body oil, grease, and sweat requires Degreaser 2.2 and is rinsed with Acidifier 2.0.

- Provides the “just right” strength—a balance between under-cleaning and over-cleaning.

- Part of a holistic leather-safe system: always follow rinse with Rinse 3.0

Soft 3.8 Key Benefits:

- Gently Cleans Without Harsh Effects – Maintains leather’s natural integrity

- Works Seamlessly with Prep 4.4 – Allows for after cleaning of sticky residue

- Prevents Rings & Browning – Ideal for pH-sensitive leathers

- Residue-Free with Rinse 3.0 – Restores leather’s pH balance for long-term care

Leather Rinsing Conditioner 3.0 by Leather Doctor® is a pH 3.0 leather-safe rinse formulated to remove suspended soil and restore the pH balance of leather, ensuring its structural integrity and long-term durability.

Rinse 3.0 Key Features & Benefits:

- Removes Suspended Soil – Lifts and extracts emulsified soiling for a clean, residue-free finish.

- Neutralizes Alkaline Residue – Restores pH balance to prevent damage from alkaline overexposure.

- Prevents Tackiness & Dye Bleeding – Stabilizes the leather structure, reducing unwanted texture changes.

- Enhances Leather’s Ionic Charge – Recharges the leather with a positive (+ve) charge, improving its ability to bond with negatively (-ve) charged tanning agents, dyestuff, and fatliquor.

- Preserves Suppleness & Durability – Helps maintain the leather’s softness, preventing stiffness and cracking.

Leather Acidifying Conditioner 2.0 by Leather Doctor® is a pH 2.0 acidifier designed to control, neutralize, and restore leather’s natural pH balance.

Acidifier 2.0 prevents leather from denaturing, which can lead to bleeding, streaking, tackiness, and structural weakness due to alkaline overexposure.

- Neutralizes alkaline contamination from cleaners, and aging sweat.

- Prevents dye bleeding and color streaking

- Reduces leather tackiness and improves texture

- Strengthens leather fibers and enhances structural integrity

Leather Hydrating Conditioner 3.3 is a leather-safe pH 3.3 aqueous solution formulated by Leather Doctor® to hydrate, relax, and restore the leather’s internal structure during cleaning, conditioning, and restoration processes - in line with its tannery science-based function.

It mimics the hydration stage of tannery pre-conditioning leather to prepare for deeper structural rejuvenation.

Hydrator 3.3 Key Benefits:

- Rehydrates dried, stiff, or collapsed fiber structure

- Restores moisture to the leather’s protein fibers, relaxing them so they can regain flexibility.

- Essential before fatliquoring (with Fatliquor 5.0) so fats and oils can penetrate deeply and bond properly.

- Displaces and flushes out impuritie

- Helps suspend and wick out residual body oils, sweat, soiling, or alkaline contamination that may have penetrated the leather.

- Balances pH and readies leather for further treatments

- The mild acidic pH of 3.3 re-aligns the ionic charges of the leather structure, making it receptive to fatliquor and protecting against pH damage.

- Helps reduce stiffness, appearance and restore suppleness

- When used alone or in conjunction with fatliquor, Hydrator 3.3 is critical for achieving uniform softness, without patchiness.

Tannery science basis

- In professional tanning and retanning, hides are hydrated before fatliquoring or coloring to ensure that treatments penetrate evenly and bond effectively.

- Hydrator 3.3 replicates this essential tannery hydration step at the restoration stage, particularly for dried-out, stiff, or aged leather.

Aniline Staining Dye 21 by Leather Doctor® is a new-generation, water-based transparent staining dye based on tannery science principles designed specifically for: Aniline Wax Pull-up.

Dye 21 Key Features:

- Transparent:

- Water-based, transparent, penetrating dye that behaves like traditional tannery stains.

- Brilliant Staining Effect:

- Enhances the natural beauty, depth, and character of the leather grain or nap rather than concealing it.

- Lively, rich color:

- Produces more vibrant and vivid results compared to most conventional liquid dyes.

- Superior lightfastness & fade resistance:

- Offers better UV stability and longer-lasting color than standard liquid dyes.

- Water-based & leather-safe:

- Compatible with Leather Doctor’s tannery science-based care system, ensuring no harm to the leather’s structure or pH balance when used as directed.

- Flexible color shading:

- Can be diluted with distilled water or Hydrator 3.3 for lighter, custom color shades.

Purpose

Aniline Staining Dye 21 is formulated for:

- Re-dyeing leather fading

- Creating uniform or shaded effects while allowing natural markings and grain to remain visible

- Maintains the leather natural breathability.

Application Methods

- Applied using lint-free towels, foam brushes, varnishing brushes, or airbrush (recommended) for best control and evenness without over-wetting.

Leather Fatliquoring Conditioner 5.0 by Leather Doctor® is a leather-safe pH 5.0 emulsion of fat, oil, and water formulated to replenish the original fatliquor content of leather’s fibrous structure.

- It restores leather’s internal lubrication, flexibility, strength, and resilience—mimicking the essential fatliquoring stage in professional tanning and retanning processes.

Fatliquor 5.0 Key Benefits:

- Lubricates and nourishes the leather structure

- Fatliquor 5.0 deposits fat and oil molecules that bond to the amphoteric protein fibers.

- These lubricate the fibrils, allowing them to slide over each other without stiffness, brittleness, or cracking.

- Reinforces tensile strength and elasticity

- Proper fatliquoring prevents fiber embrittlement and maintains leather’s natural strength and softness.

- Restores suppleness and prevents future damage

- Leather loses fatliquor over time due to aging, heat, sunlight, alkaline exposure, or cleaning.

- Replenishing it prevents shrinkage, stiffness, and cracks.

- Provides long-term structural protection

- Maintains leather’s dimensional stability and ability to flex without damage.

Tannery science basis:

- In the tannery, fatliquoring is one of the final and most critical stages after tanning and dyeing.

- It ensures that leather stays soft, strong, and flexible as it dries.

- The fats and oils form a molecular film around the protein fibers, acting as internal lubricants.

Fatliquor 5.0 brings this same process to leather restoration.

It ensures the leather is not just “looking good on the surface” but structurally rejuvenated from within.

Leather Conditioner Wax Pull-Up 8.6 by Leather Doctor® is a rejuvenator for restoring the diminishing aniline wax effect lost through usage, aging, or cleaning.

It is highly recommended that the primary leather softening process of hydration and fatliquoring be completed to satisfaction before applying the secondary wax pull-up effect.

The Importance of Hydration & Fatliquoring Before Applying Wax Pull-Up 8.6:

Before restoring the pull-up effect, it is highly recommended to complete the primary softening process through hydration and fatliquoring. Here's why:

1. Hydration – Relax, Revive & Rejuvenate

Over time, leather loses moisture due to aging, environmental exposure, and cleaning. Dry leather fibers become stiff and prone to cracking. Hydration helps:

- Relax stiff fibers and correct shrinkage

- Open up the leather structure for better fat and oil absorption

- Reduce dryness-induced creases and stiffness

2. Fatliquoring – Restoring Softness & Strength

Once hydrated, leather requires fatliquoring, which replenishes the natural fats and oil that provide:

- Softness and flexibility

- Internal lubrication to prevent stiffness and cracking

- Resistance against premature wear and aging

3. Wax Pull-Up Effect – Finishing Touch for Beauty & Function

Only after leather is fully softened should Wax 8.6 be applied. This ensures:

- A revived wax pull-up effect for a rich, dynamic look

- Enhanced suppleness without overloading stiff leather

- Long-lasting protection and beauty

By following this two-step restoration process, you maximize the longevity and luxurious feel of aniline wax pull-up leather.

Leather Adhesion Primer 73 by Leather Doctor® is a compact resin primer designed to smooth, seal, and enhance adhesion before color coating.

Primer 73 is formulated and designed to:

- Smooth and seal leather surfaces.

- Enhance adhesion for color coating.

- Build uniform surfaces over rough or abraded areas.

- Assist in removing deteriorated finishes.

- Reactivate aniline dyestuff to some extent.

Aniline Gloss Coating Dye 76 by Leather Doctor® is a next-generation water-based transparent surface coating dye formulated for vivid, brilliant color coverage on leather.

Unlike traditional penetrating dyes, Dye 76 forms a transparent surface film, enhancing color intensity, uniformity, and gloss while preserving the natural beauty of the leather grain.

Dye 76 Key Features:

- Transparent coating allows the natural grain to show through — akin to varnishing fine wood.

- Provides bright, vivid color enhancement over existing aniline or bronzing-stained dye effects (e.g., over Aniline Staining Dye 21).

- Revitalizes and enriches aged or faded finishes without masking the leather’s character.

- Suitable for use as a final color gloss coat or layered over base dyes.

- Water-based, leather-safe formula compatible with Leather Doctor® systems.

Aniline Finish Topcoat Gloss 76 by Leather Doctor® is a premium water-based topcoat designed to seal and protect all gloss aniline leathers.

It prevents color crocking and bleeding while enhancing the leather's appearance with a clear, gloss finish.

Gloss 76 features: Gloss Protective Topcoat for Aniline Leathers

- Heavy-Duty Protection – Formulated for maximum toughness and flexibility.

- Crystal-Clear Gloss – Fine particulate urethane-resin emulsion delivers a sleek, glossy finish.

- Customizable Durability – Boost water resistance and resolve tackiness by adding Crosslinker 64.

Recommended Add-On:

- Crosslinker 64 (Sold separately) – Enhances topcoat performance and longevity.

Instruction:

1️⃣ Degreasing with Degreaser 2.2

- Degreaser 2.2 is shaken well to coagulate.

- It is saturated to reach penetrated soiling with appropriate brushes and erasers and extracted with Towel 5 or equivalent until it shows clean.

- It is reapplied and allowed to dwell 3 to 30 minutes or before it dries for a complete soiling suspension and extracted until it shows clean.

2️⃣ Cleaning with Soft 3.8

- Before use, the Soft 3.8 concentrate, a ratio of 1 to 64, is mixed with 224g distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is mixed well, applied, and brushed with Brush 1, Eraser 4 and towel extract until the towel shows clean.

3️⃣ Rinsing with Rinse 3.0

- Before use, the Rinse 3.0 concentrate, a ratio of 1 to 40, is mixed with 222g distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is mixed, applied, and brushed with Brush 1, Eraser 4 and extracted with a towel until it shows clean and the leather takes a squeaky, healthy feel.

4️⃣ Acidifying with Acidifier 2.0

- Before use, the Acidifier 2.0 concentrate, a ratio of 1 to 25, is mixed with 224g distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is applied directly, brushed, and extracted with Towel 5 until clean.

- It is kept for 3 to 30 minutes to control dye bleeding or surface tackiness.

- Treatment is complete with a test for a healthy squeaky feel.

5️⃣ Hydrating with Hydrator 3.3

- Before use, the Hydrator 3.3 concentrate, a ratio of 1 to 25, is mixed with 218g of distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is applied from the surface or accelerates saturation by working on the reverse side for a quick darkening effect.

- A 3 minutes to 72 hours dwell to activate dormant dyestuff to resurface for an effective relaxing results.

- Creases, wrinkles, or shrinkage is stake, massage, and stretch to dimension ready for fatliquoring.

- Leaving overnight for long dwell, Leather Mold Odor Killer 3.6 may be needed to control potential mold growth.

6️⃣ Dye Staining with Dye 21

- Before use, the Dye 21 concentrate, a ratio of 1 to 9, is mixed with 51g of distilled water, or 1 inches from the top of the 4oz bottle.

- It is stain dyed with lint-free paper towels, plush, foam, or high-quality varnishing brushes to even out appearance.

- Fast dry with an air blower and the surface is inspected for evenness or correction until satisfaction.

7️⃣ Softening with Fatliquor 5.0

- Before use, the Fatliquor 5.0 concentrate, a ratio of 1 to 5, is mixed with 189g warm distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is applied and redistributed with appropriate brushes or pads until the thickness of the leather is saturated.

- The application is repeated each time water content evaporates, until it absorbs no more.

- Sticky residue is further driven into the leather structure or rinsed off with Hydrator 3.3.

- Fatliquored leather is left to dry naturally for extra softness.

- Fatliquored leather is further staked, massaged, flexed or stretched accordingly with a little wet back with Hydrator 3.3 until dry for extra suppleness.

- Surface tension is also inspected with Hydrator 3.3 using a folded towel to check for even absorbency, ready for dye refinishing.

8️⃣ Effecting with Wax 8.6

- Before use, the Wax 8.6 concentrate, a ratio of 1 to 9, is mixed with 204g warm distilled water, or 1.5 inches from the top of the 8oz bottle.

- Apply and spread to saturate sufficiently with Brush 1 evenly to produce a darkening effect.

- Allow up to 8 hours of natural drying time or until crystalline is apparent.

- Activate the crystalline wax deposit with a heat blower or hairdryer to a natural gloss.

9️⃣ Priming with Primer 73

- Before use, the Primer 73 concentrate, a ratio of 1 to 1, is mixed with 28g of distilled water, or 1 inches from the top of the 4oz bottle.

- Apply Primer 73 evenly using Brush 1 or a white 3M scouring pad.

- Work it into grooves and worn areas.

- Wipe off excess until a lint-free towel shows clean.

- Allow to dry naturally or speed dry.

- For darkening areas, stretch gently with a spatula or spoon to lighten out appearance.

![]() Dyeing with Dye 76

Dyeing with Dye 76

- Before use, the Dye 76 concentrate, a ratio of 1 to 1, is mixed with 57g distilled water, or 1 inches mark from the top of the 4oz bottle.

- Check for surface tension with Hydrator 3.3 to ensure free of surface grease to avoid poor adhesion.

- It is applied onto the surface by Foam 2, folded Towel 5, or airbrushing for the desired result.

1️⃣1️⃣ Sealing with Gloss 76

- Before use, the Gloss 76 concentrate, a ratio of 1 to 2, is mixed with 76 g distilled water, or 1 inches mark from the top of the 4oz bottle.

- Use a lint-free cloth for padding, a varnishing brush, or an airbrush for the most professional finish.

- Allow each layer to dry completely before applying the next coat for optimal results.

1️⃣2️⃣ Conditioning with Conditioner B

- Before use, Conditioner B concentrate, a ratio of 1 to 19, is mixed with 215g distilled water, or 1.5 inches from the top of the 8oz bottle.

- It is mixed, applied, and spread with a Foam 2 or folded Towel 5 and is ready to use when dry.

How to Identify Leather Stains?

Stain identification is crucial for effective treatment and is based on six key factors:

✅ Appearance

- Observing how the stain looks can indicate whether it is a spill, rub-on, penetration, or surface deposit.

- Some stains may cause dye or finish damage, revealing changes in the leather’s color or texture.

✅ Odor

- Smelling the stain can help identify its source.

- Common odors include:

- Moldy (fungal growth)

- Smoke (fire or cigarette exposure)

- Putrid (decaying organic matter)

- Ammonia (urine contamination)

✅ Color

- Color provides a clue to the staining substance but can change over time due to oxidation.

- The leather’s natural color may also influence how the stain appears.

- Red stains: Could be from wine, blood, lipstick, nail polish, or beverages.

- Blood stains: Can oxidize and shift from red to tan, then to black.

✅ Feel-of-Hand

- Touching the stain helps determine its type:

- Sticky: Likely from candy, beverages, or sugary substances.

- Brittle and stiff: Could be nail polish, paint, or shellac.

- Greasy smear: Often caused by lipstick, oils, or butter.

✅ Location

- The stain’s location on the leather provides hints about its origin.

- Headrests & armrests: Usually stained by body oil, sweat, and grease.

- Seat cushions: Often show food or beverage spills.

✅ Buildup or Absorbed

- Stains can be surface-level (built-up) or deeply absorbed into the leather.

- Built-up stains (common on pigmented leather) include paint, food residue, and ink.

- Absorbed stains (common on nubuck, aniline, and unfinished leather) include wine, tea, and coffee.

- Combination stains: Some stains contain both absorbed and surface elements, such as lipstick, ink, and mustard.

- Protein-based stains: Examples include blood, dairy, and egg-based spills.

- Oil-based stains: Often come from grease, butter, and lotions.

- Colloidal stains: May require specialized treatments.

✅ Additional Considerations

- Sweat stains can chemically alter leather, causing tackiness (when dry) or sliminess (when wet).

- Dye stains may show up when wiping with a white towel—this indicates color crocking.

- Fatliquor leaching (spew) appears as a milky film and causes leather to become stiff and prone to cracking.

By carefully identifying stains, you can apply the appropriate Leather Doctor® solutions to restore leather to its original beauty.

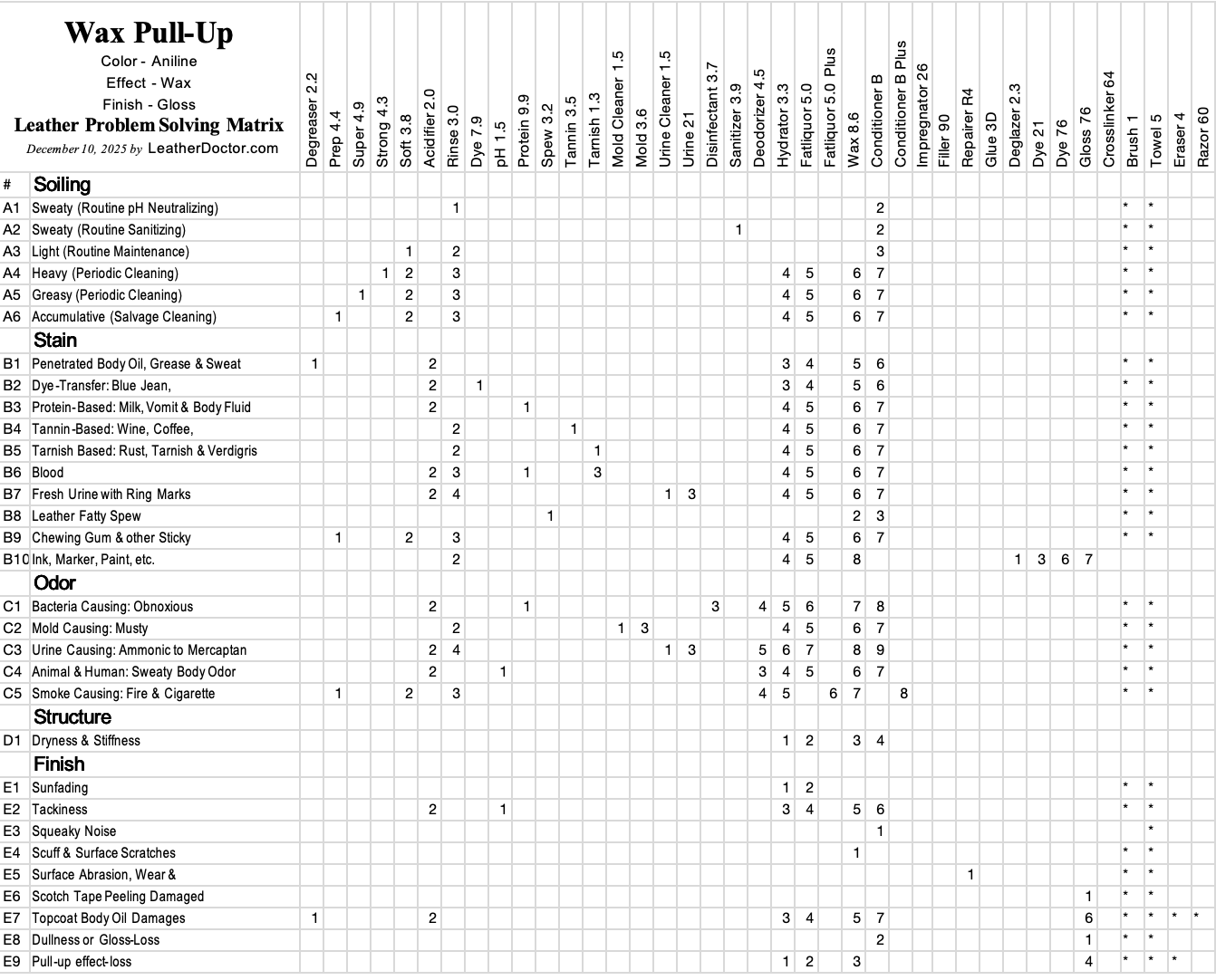

How to Use this Leather Problem-Solving Matrix?

- This matrix categorizes common issues with Vachetta into five groups:

- Soil, Stain, Odor, Structure, and Finish (listed in the left column).

- Corresponding recommended products are displayed across the top row.

- Each number within the matrix indicates the steps required to address the problem holistically.

For example:

If a leather issue involves an unknown compound that combines soil, stain, and odor, follow the sequence across the matrix, combining necessary steps from each category.

The process should always conclude with:

- Hydrator 3.3 to rehydrate and relax the leather.

- Fatliquor 5.0 to replenish lost fats and oils, restoring suppleness.

- Conditioner B conditioning the leather for ongoing durability.

Your opinions, insights and review are precious and will help us to solve your leather problem more efficiently.

Upgraded July 29, 2025 | August 19, 2025 | December 10, 2025 by Roger Koh.